Cambrex Waltham (Snapdragon Chemistry)

Our team members with Snapdragon Chemistry Inc., a Cambrex Company, specialize in chemical process development and manufacturing services, leveraging state-of-the-art technology to optimize your...

About the plant

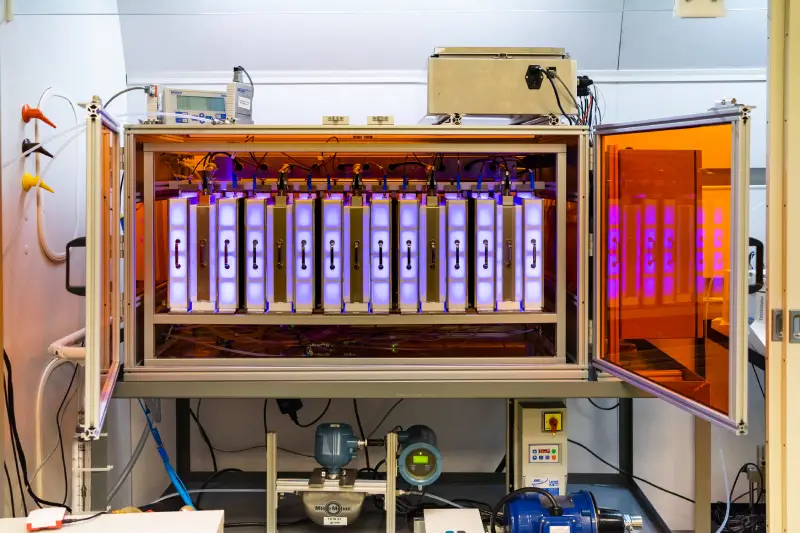

Our team members with Snapdragon Chemistry Inc., a Cambrex Company, specialize in chemical process development and manufacturing services. We leverage state-of-the-art technology to optimize your process and prepare scaled quantities of your product. Our chemists and engineers work with you to provide reactor design and set-up and portfolio optimization. We also offer comprehensive GMP manufacturing at Waltham with seamless technology transfer and scale-up.

Facility Details

- Process development

- Continuous manufacturing

- Reactor design and build

- Portfolio optimization

- GMP manufacturing

Compliance

- EMA (EU GMP)

- FDA (cGMP)

- Health Canada (Canada GMP)

- MFDS/KFDA (Republic of Korea GMP)

- PMDA/MHLW (Japan GMP)

- MHRA (UK GMP)

Activity

- CHEMICAL-SYNTHETIC, RSM (Raw Starting Materials), Intermediates, Fine Chemicals, API (Active Pharmaceutical Ingredients), Excipients, Building Blocks manufacturing

Features

- Uses: Investigational, Commercial (Phase IV), Preclinical, Phase I, Phase II, Phase III, Human

- Toxicity (OEB classification): 1 / low-hazard (PDE > 5,000 µg/day), 2 (PDE = 1,000 - 5,000 µg/day), 3 (PDE = 100 - 1,000 µg/day)

- Controlled substance: N/A

- BSL: N/A

- Therapeutic areas: N/A

- Markets: FDA (USA), EMA (EU), PMDA (Japan), Health Canada (Canada), MHRA (UK), MFDS (South Korea)

Batch Size / Reactor

- Small, Medium, 1 - 10 L, 10-100 L, 100 - 1,000 L

Services

- Development services, Manufacturing services, Analytical / QC services, Quality Assurance services, Logistics, Preformulation studies, R&D, Formulation / Galenic design, QbD (Quality by Design), Process development, Process optimization, Process validation, Lyophilization cycle development, Stability studies design, Stability studies execution, ICH Stability studies, Comparability studies, Tech transfer, Pilot plant, Formulation mixing, Lyophilization, Research batches, Engineering batches, Scale-up, Pilot batches, Registration batches, Batch records, Analytical methods development, Analytical methods validation, Release testing of raw materials, Release testing of product, Analytical methods transfer, Batch certification / release, GMP documentation, Storage, Distribution, GDP, Salt screening, Co-crystal screening, Polymorph screening, Crystallization screening, Chiral resolution screening, Milling, Safety studies, Solid form selection, Crystal engineering, PGI assessment (Genotoxic Impurities), Nitrosamine risk assessment, Customized block synthesis, Impurity synthesis

Address

360 2nd Ave, Suite C Waltham, MA 02451, USA

Year

2014

United States

United States

Other plants of this company

Cambrex High Point

Cambrex High PointCambrex High Point focuses on the development and manufacture of active pharmaceutical ingredients (APIs) to support clinical trials from Phase I to Phase III, as well as small-scale commercial manufacturing.

Cambrex Edinburgh

Cambrex EdinburghCambrex Edinburgh offers world-class solid form screening programs, including salt screening, polymorph screening, co-crystal screening, crystallization screening, and further specialized screening activities.

Cambrex Charles City

Cambrex Charles CityOur 400+ team members in Charles City specialize in late-phase and commercial API development and cGMP manufacturing.

Contact us

If you have any questions or suggestions, click here. We will be happy to assist you.