Cambrex High Point

Cambrex High Point focuses on the development and manufacture of active pharmaceutical ingredients (APIs) to support clinical trials from Phase I to Phase III, as well as small-scale commercial...

About the plant

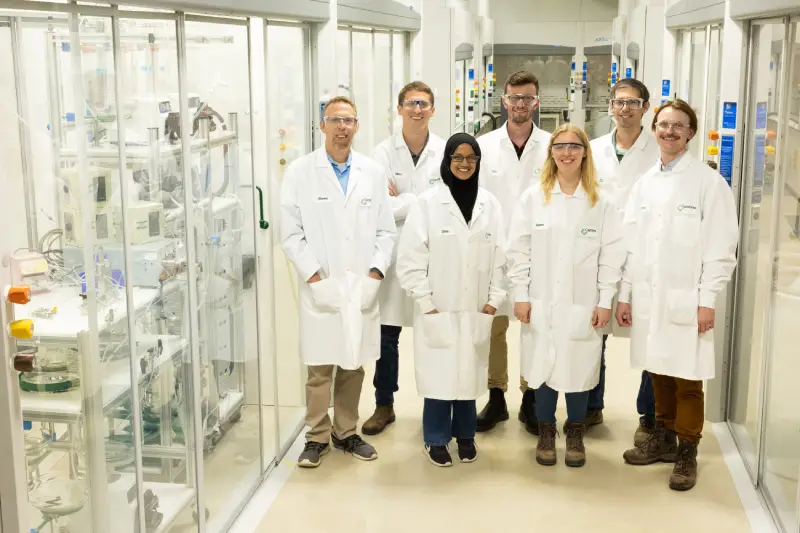

Our team in High Point focuses on the development and manufacture of active pharmaceutical ingredients (APIs) to support clinical trials from Phase I to Phase III, as well as small-scale commercial manufacturing starting in late 2023. Our integrated team of experienced process chemists, process engineers, and analytical chemists offer state of the art chemistry and manufacturing support and expertise.Our team of PhD-level process and analytical chemists and research engineers offer GMP API development services.

Our site is also licensed with the US Drug Enforcement Administration (DEA) to manufacture Schedule II to Schedule V controlled substances.

Facility Details

- Technical project management- core strength with Ph.D. PMs averaging 15 years’ experience.

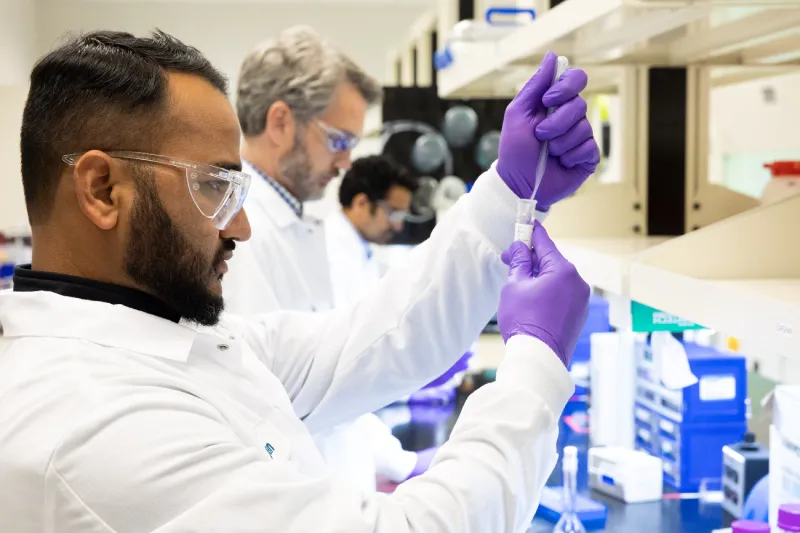

- Chemistry laboratory (custom synthesis, discovery research, and process development)

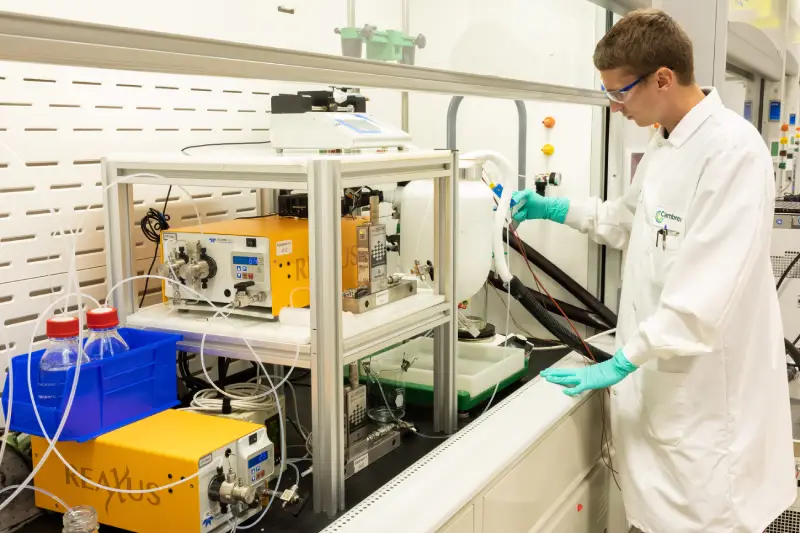

- Process engineering laboratory (continuous flow process and separations process development)

- 8 kilo-scale reactors (20 L, 30 L and 100 L) for GMP synthesis

- Pilot-scale reactors (200 L, 800 L, 1,200 L and 2,000 L reactors) for GMP synthesis

- Temperature range from -70°C to +160°C (GMP pilot plant capability)

- 78 bench-top hoods and 18 walk-in hoods for chemistry projects

- Controlled substance R&D and manufacturing capability Schedule II to Schedule V

- GMP-compliant chemical storage with quarantine for raw materials, intermediates, and finished products

- Process safety testing

- Analytical services

- Project management

- Strong regulatory history

Compliance

- EMA (EU GMP)

- FDA (cGMP)

- Health Canada (Canada GMP)

- MFDS/KFDA (Republic of Korea GMP)

- PMDA/MHLW (Japan GMP)

- MHRA (UK GMP)

Activity

- CHEMICAL-SYNTHETIC, RSM (Raw Starting Materials), Intermediates, Fine Chemicals, API (Active Pharmaceutical Ingredients), Excipients, Building Blocks manufacturing

Features

- Uses: Investigational, Commercial (Phase IV), Phase I, Phase II, Phase III, Human

- Toxicity (OEB classification): 1 / low-hazard (PDE > 5,000 µg/day), 2 (PDE = 1,000 - 5,000 µg/day), 3 (PDE = 100 - 1,000 µg/day), 4 / HPAPI (PDE = 10 - 100 µg/day)

- Controlled substance: High potential for abuse & no medical use, High potential for abuse & medical use, Lower potential for abuse, Low potential for abuse, Lowest potential for abuse

- BSL: N/A

- Therapeutic areas: N/A

- Markets: FDA (USA), EMA (EU), PMDA (Japan), Health Canada (Canada), MHRA (UK), MFDS (South Korea)

Batch Size / Reactor

- Small, Medium, 1 - 10 L, 10-100 L, 100 - 1,000 L, 1,000 - 2,000 L

Services

- Development services, Manufacturing services, Analytical / QC services, Quality Assurance services, Logistics, Preformulation studies, R&D, Formulation / Galenic design, QbD (Quality by Design), Process development, Process optimization, Process validation, Lyophilization cycle development, Stability studies design, Stability studies execution, ICH Stability studies, Comparability studies, Tech transfer, Pilot plant, Formulation mixing, Lyophilization, Research batches, Engineering batches, Scale-up, Pilot batches, Registration batches, Batch records, Analytical methods development, Analytical methods validation, Release testing of raw materials, Release testing of product, Analytical methods transfer, Batch certification / release, GMP documentation, Storage, Distribution, GDP, Salt screening, Co-crystal screening, Polymorph screening, Crystallization screening, Chiral resolution screening, Milling, Safety studies, Solid form selection, Crystal engineering, PGI assessment (Genotoxic Impurities), Nitrosamine risk assessment, Customized block synthesis, Impurity synthesis

Address

4170 Mendenhall Oaks Pkwy High Point, NC 27265, USA

Year

1999

United States

United States

Other plants of this company

Cambrex Milan

Cambrex MilanOur Cambrex Milan site develops and manufactures proprietary products (generic APIs) and provides contract manufacturing services for intermediates and custom APIs at commercial scale.

Cambrex Charles City

Cambrex Charles CityOur 400+ team members in Charles City specialize in late-phase and commercial API development and cGMP manufacturing.

Cambrex Longmont

Cambrex LongmontCambrex Longmont location specializes in the early development of small molecule pharmaceutical products in a fully integrated drug substance and drug product facility.

Contact us

If you have any questions or suggestions, click here. We will be happy to assist you.