Liof Pharma S.L.U.

Reliable CDMO partner for aseptic manufacturing and lyophilization of biologics and injectable drugs.

About the plant

First-class partner in the field of pharmaceutical contract manufacturing, we use our expertise in Pharmaceutical R&D, Aseptic Filling, Lyophilization, Micro/Nanoencapsulation processes and extensive knowledge of international requirements to enable your product meets the most demanding quality standards and customer needs.

We offer development and preclinical supply services including galenic development, preclinical development, production of pilot lots and design of preclinical trials for efficacy, safety as well as other complementary studies for technology scale up.

We have extensive experience working with complex substances such as biologics, including monoclonal antibodies, peptides and other proteins. Lyophilization and micro/nanoencapsulation are some of our areas of expertise. Knowing how to design an appropriate manufacturing process is critical for both regulatory and efficiency purposes.

Clinical manufacturing (Preclinical, Phase I, Phase II, Phase III) service is offered using NoncGMP/cGMP, semi-automated/automated filling processes matching all the customer needs. Manufacturing steps include sterile filtration, preparation of primary packaging materials (e.g., cleaning, sterilization), preparation of the formula and lyophilization if required – primarily biologics such as proteins and monoclonal antibodies.

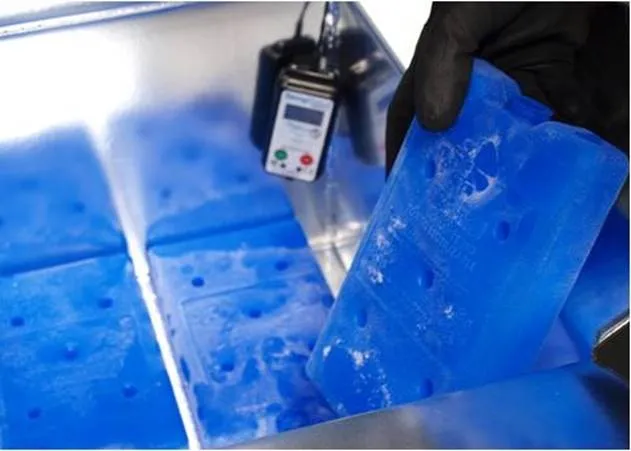

We have extensive knowledge manufacturing sensitive, high-value biologics and aseptic processing. Our aseptic filling technologies and lyophilization methods meeting the latest state-of-the-art are among the most advanced in the pharmaceutical contract manufacturing industry incorporating HVAC automatic control, continuous particle monitoring, automatic cleaning, sterilization and other automatic processes and testing.

Our analytical quality control measures include testing raw materials, packaging materials, bulk solutions, in-process materials and finished products.

We also offer the design and execution of stability studies.

Compliance

- EMA (EU GMP)

- FDA (cGMP)

- ANVISA (Brazil B-GMP)

- Roszdravnadzor (Russia GMP)

Activity

- FDF / DRUG PRODUCTS manufacturing

Features

- Uses: Investigational, Commercial (Phase IV), Preclinical, Phase I, Phase II, Phase III, Human, Veterinary

- Toxicity (OEB classification): 1 / low-hazard (PDE > 5,000 µg/day), 2 (PDE = 1,000 - 5,000 µg/day), 3 (PDE = 100 - 1,000 µg/day)

- Controlled substance: N/A

- BSL: 1

- Therapeutic areas: N/A

- Markets: INVIMA (Colombia), FDA (USA), EMA (EU), MHRA (UK), ANVISA (Brazil), Russian Health Authorities

Batch Size / Reactor

Services

- Development services, Manufacturing services, Analytical / QC services, Quality Assurance services, Packaging, Logistics, Formulation / Galenic design, Process validation, Stability studies execution, ICH Stability studies, Tech transfer, Pilot plant, Formulation mixing, Lyophilization, Research batches, Engineering batches, Scale-up, Pilot batches, Registration batches, Batch records, Analytical methods validation, Release testing of raw materials, Release testing of product, Bioanalysis, Analytical methods transfer, QP in house, Batch certification / release, GMP documentation, Primary packaging, Secondary packaging, Labeling, Serialization, Storage, Distribution, GDP

Address

Hermanos Lumiere 5

Year

2011

Spain

Spain

Contact us

If you have any questions or suggestions, click here. We will be happy to assist you.